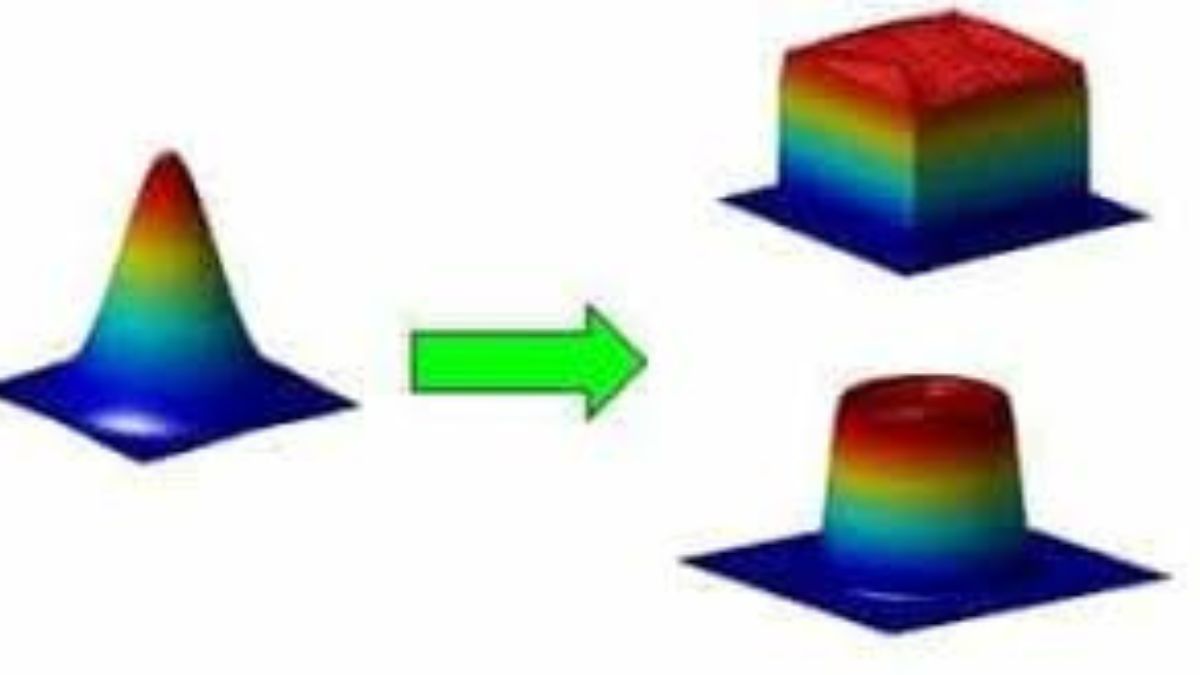

Laser marking machines have transformed many industries. They can imprint high-quality, permanent text and graphics on various products. Manufacturers can choose between two beam types, Gaussian and Top Hat. They use them for different marking techniques. One central area to appreciate in the choice of laser marking technology is the distinction between the Gaussian and Top Hat beams. This article will discuss, in detail, the two types of laser beams. They make laser marking machines flexible and efficient.

Understanding Gaussian Beams

Gaussian beams represent the most common beam profile in laser marking machines. Their name comes from the power function of the Gaussian function. It describes the beam’s intensity distribution along its propagation direction. The critical feature of the Gaussian beam is the presence of the ‘hole’ in the center of the beam through which the intensity is high, gradually decreasing toward the edge.

Features and Advantages

- a) Single Spot Focusing: Using Gaussian beams, one can focus on a single spot, thus providing high marking precision with a small focal depth. This technique also allows for the accurate execution of extra-small and precise details and lines with relative ease.

- b) Higher Energy Efficiency: A Gaussian beam needs less energy to mark with a laser. So, it marks faster than other beam types.

- c) Flexibility: A Gaussian beam’s use depends on precise positioning and calibration. It can work on different materials, like metals, plastics, and ceramics. So, both can be used for various purposes in other industries.

Limitations

- a) Heat-Affected Zone (HAZ): A high energy density in the laser beam’s focal area might cause a larger heat-affected zone around the mark. This can be bad as it may alter or distort the substrate material.

- b) Limited Marking Area: The smaller focal spot may mark a smaller area than expected for a given application and material thickness.

Exploring Top Hat Beams

Top-hat beams are also called flat-top or uniform beams. Their intensity pattern resembles a top hat along the propagation axis, which gives them a long, even energy distribution—better than the Gaussian beam’s donut-shaped one. Top-hat beams can be produced by employing SLMs and DOEs.

Features and Advantages

- a) Uniform Intensity Distribution: Unique to Top Hat beams, the energy output at the marked region is spread continuously, meaning no point is overheated.

- b) Large Marking Area: Top Hat beams have a sharp distribution. They can produce larger, evenly distributed marks than Gaussian beams, making them ideal for applications needing broad, uniform marking.

- c) Reduced Material Distortion: Lower heat concentration cuts warpage. It improves mark quality and lowers the risk of harming the substrate.

Limitations

- a) Slower Marking Speeds: Top Hat beams have a drawback compared to Gaussian beams. They require more energy to achieve the same marking effect. So, marking speeds can be slower.

- b) Limited Flexibility: Top Hat beams may have stricter marking material limits than Gaussian beams. Their marked points must be well-confocal.

Application Considerations

When deciding between Gaussian and Top Hat beams for laser marking machine applications, several factors should be considered:

- a) Material Compatibility: Select the beam profile based on the substrate’s material. This will maximize marking quality and minimize adverse effects.

- b) Marking Quality: An optimal beam profile should, ideally, match the required marking quality, size, and uniformity. For finer detail work, Georgia beams are better. They have small focal dimensions. For more significant, uniform diffraction spots, use Top Hat beams.

- c) Process Efficiency: The marking should be as fast and energy efficient as needed. However, the marking with the German TOP HAT beams will differ greatly from the Gaussian beams. In some cases where modal speed or energy efficiency is considered a priority, Gaussian beams may be preferred.

Conclusion

A brief about Gaussian and Top Hat beams are as follows are Two types of laser beams which are used in Laser marking – learn more about Gaussian Beam VS Top Hat Beam, both have their benefits and drawbacks. Top Hat beams have some advantages over Gaussian beams. They have a more uniform intensity, a larger marking area, and less material deformation. But, Gaussian beams are more accurate, efficient, and compatible with materials. Knowing the technical details and requirements for each beam profile is key. It helps laser marking system producers to fine-tune their lasers. This ensures they achieve the desired results.

Today’s laser marking results show that Gaussian and Top Hat beams will be critical to the future of industrial laser marking. As laser technology advances, it will improve flexibility and efficiency in many applications.