For businesses and industries where moisture control is non-negotiable, hygropack stands out as an effective, innovative solution. Whether in pharmaceuticals, food packaging, or consumer electronics, the need for reliable desiccant technology has never been more integral to maintaining quality and expanding product life cycles. But what exactly is hygropacks, and why is it becoming a go-to choice for professionals across various industries?

This guide will not only explain how hygropacks works but also explore its wide-ranging benefits and practical applications. By the end, you’ll understand why investing in hygropacks isn’t just smart—it’s essential for industries where moisture can be a deal-breaker.

What is hygropack?

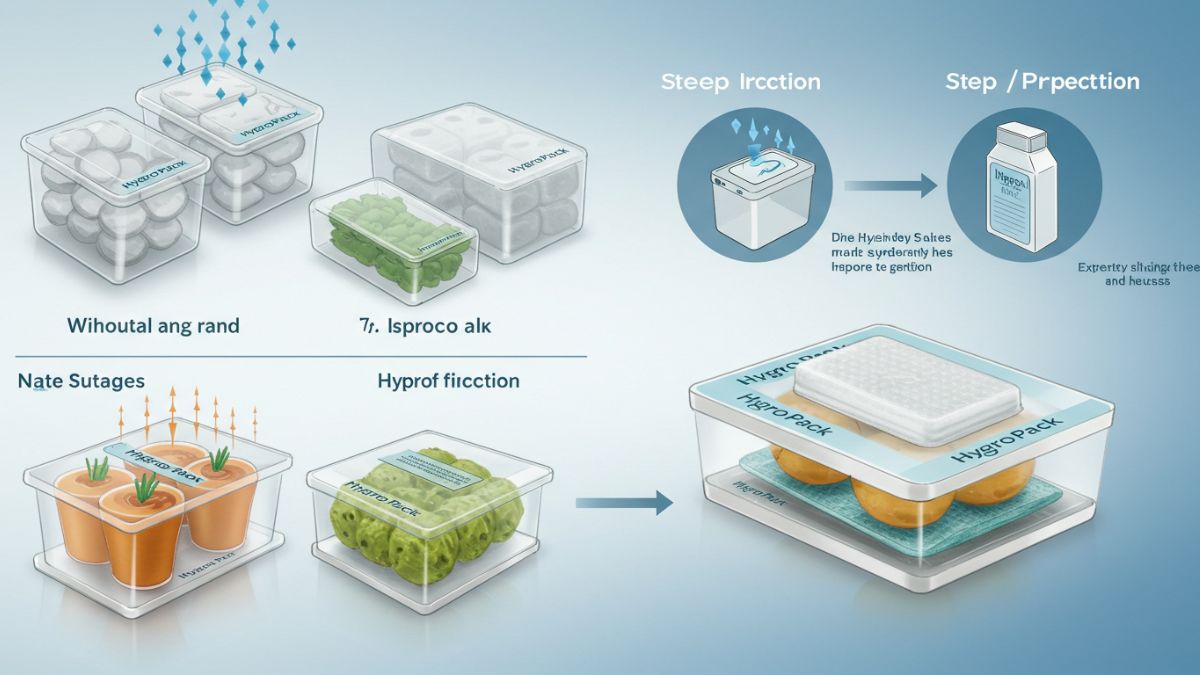

At its core, hygropack is a compact, high-performance desiccant solution crafted to provide superior moisture control. Whether you’ve bought a new electronic device or packaged food, you’ve likely encountered small pouches labeled “desiccant—do not eat.” These desiccants play a vital role in protecting products from moisture and humidity.

Hygropacks takes this concept further by offering tailored moisture-control technology packed in a highly durable and functional format. It’s designed to meet the evolving needs of businesses by combining cutting-edge material science with robust usability. Think of it as the desiccant of the future—targeted, efficient, and designed for optimal performance.

Why is hygropack Important?

Excessive moisture can be devastating to many products, causing:

- Mold growth

- Degradation of electronics

- Spoiled food

- Compromised pharmaceuticals

Hygropack prevents all of the above by effectively absorbing atmospheric moisture, ensuring the integrity and longevity of the product it protects.

Industries are now turning to smarter, more efficient solutions to ensure quality control—and hygropacks fits the bill perfectly.

The Benefits of hygropack

Why should your business or industry trust hygropack? Here are the standout benefits:

1. Industry-Specific Customization

Hygropack isn’t just one-size-fits-all. It’s designed to accommodate the unique needs of various industries. Does your electronic device require a specific moisture absorption rate? Hygropacks can be tailored to achieve that precision. From pharmaceuticals that demand minimal humidity to food packaging with high sensitivity, hygropacks adapts to meet highly specialized requirements.

2. Enhanced Efficiency in Moisture Control

Unlike conventional desiccants that may falter in highly humid environments or prolonged usage, hygropack excels. Whether used in airtight containers or more open packaging, its high-efficiency absorbent materials actively combat moisture infiltration, ensuring long-lasting protection.

3. Streamlined Packaging Design

Modern production values aesthetics and functionality equally. Hygropacks offers a minimalistic yet highly practical design that doesn’t compromise on branding or space constraints. By being compact yet highly robust, it integrates seamlessly with a diverse range of packaging materials and products.

4. Eco-Friendly Materials

Sustainability is a growing concern across industries, and hygropack delivers on this front. Made with eco-friendly materials, many variations ensure waste reduction without sacrificing performance. For environmentally conscious businesses, this is an important step toward greener operations.

5. Regulatory Compliance

Certain industries like pharmaceuticals and food manufacturing face stringent regulatory and safety standards. Hygropack is designed to meet global compliance criteria across sectors, giving you peace of mind that your products not only work effectively but also adhere to strict safety guidelines.

6. Cost-Efficiency

Finally, hygropacks proves its mettle with cost efficiency. Its longevity and high moisture control capabilities lower long-term risks related to product degradation, meaning fewer returns, lower waste levels, and higher profitability.

Applications of hygropack Across Various Industries

Now that we’ve detailed why hygropack stands head and shoulders above competitors, let’s break down its practical uses in real-world settings.

1. Pharmaceuticals

Medications are highly sensitive to moisture, often requiring specific storage conditions to maintain their effectiveness. Hygropack ensures drugs stay potent by preventing the formation of moisture that can compromise chemical stability.

Example: Protecting powdered antibiotics or gel capsules from degradation during global shipping is essential yet challenging—a challenge hygropacks excels at overcoming.

2. Food Packaging

Whether it’s snacks that need to maintain their crispness or dried fruits that need to stay fresh, humidity can significantly reduce product quality. Hygropacks ensures moisture doesn’t creep into the food industry’s most delicate offerings.

Example: By preserving the original texture of foods like crackers or granola bars, hygropacks amplifies both customer satisfaction and shelf life.

3. Consumer Electronics

From smartphones to high-performance cameras, electronics are naturally susceptible to moisture damage. Hygropack acts as a protective barrier, ensuring these devices remain functional even in fluctuating environments.

Example: Imagine ensuring a camera delivers peak performance while stored in tropical conditions. Hygropacks makes that a reality.

4. Logistics and Supply Chain

Long-distance shipping exposes products to fluctuating moisture levels, particularly across sea routes or extended trips. Hygropacks is a reliable companion for ensuring that fragile goods arrive intact.

Example: Think of delicate European chocolates shipped across continents—they arrive fresh rather than ruined by condensation.

5. Industrial Machinery

Even machinery requires a moisture-free environment to perform optimally. Gears, belts, and internal components all benefit from proper moisture control, especially during storage periods.

Example: Hygropack safeguards high-value machinery by reducing risks like rust or degradation, even if stored for extended periods in non-climate-controlled facilities.

Tips for Successful hygropack Integration

Here are actionable steps to ensure you maximize the benefits of hygropack in your industry:

Start with Proper Analysis

Evaluate your product’s moisture tolerance and match it with the appropriate hygropack configuration. Factors like expected storage time, packaging design, and climate conditions play a huge role here.

Scale Gradually

If you’re new to hygropack, consider starting with smaller batches in key product lines. Measure outcomes like customer feedback or product durability before scaling further.

Educate Your Team

Train your team on how to handle and implement hygropacks within production and packaging processes. Even something as simple as learning to assess when replacements are needed can make a big difference.

Conclusion

Implementing hygropack solutions can significantly enhance product quality, longevity, and customer satisfaction when used effectively. By taking a strategic approach—starting with thorough analysis, gradual scaling, and proper team education—you can seamlessly integrate this technology into your operations. With continuous monitoring and adjustments, hygropacks can become a valuable tool in maintaining the integrity of your products and meeting the evolving demands of your industry.

FAQ’S

1. What is a hygropack?

A hygropack is a moisture control solution commonly used in packaging to maintain appropriate humidity levels, ensuring the quality and longevity of products.

2. How do I know when to replace a hygropack?

Most hygropacks include indicators or guidelines for replacement. It’s essential to monitor the state of the package and replace it as suggested by the manufacturer to preserve optimal performance.

3. Can hygropack be used for all types of products?

Hygropacks are versatile but are particularly effective for items sensitive to moisture, such as food, electronics, and pharmaceuticals. Always consult product-specific guidelines to confirm compatibility.